Die Casting Services for High-Quality, Precision Components

Are you in need of high-quality, precise die casting for your manufacturing needs? Look no further! Our die casting services offer a cost-effective solution for producing complex and intricate metal parts in a variety of alloys.

Our state-of-the-art equipment and highly skilled team of engineers and technicians allow us to produce parts with tight tolerances and smooth surface finishes. We use the latest technology in the die casting process, such as vacuum and low pressure die casting, to ensure the highest quality and consistency in every part we produce.

Our team has a wealth of experience in die casting, and can work with you to optimize your design for the die casting process, ensuring that your parts meet your exact specifications. We also offer value-added services such as machining, finishing, and assembly to provide you with a finished product that is ready to use.

We have a wide range of capabilities, and can handle projects of any size, from small, high-precision parts to large, complex components. We also offer competitive pricing and quick turnaround times, making us an ideal choice for both high-volume production and prototyping needs.

Die Casting Types from TeraPool Groups

Hot chamber die casting

This method is used for casting metals with low melting points, such as zinc and magnesium. A crucible is used to melt the metal, which is then injected into the die under high pressure.

Cold chamber die casting

This method is used for casting metals with high melting points, such as aluminum and copper. The metal is melted in a separate furnace and then transferred to the injection cylinder, which injects the metal into the die under high pressure.

Vacuum die casting

This method uses a vacuum to remove air and gases from the die before the metal is injected, resulting in a higher-quality casting with fewer defects.

Squeeze casting

This method is also known as thixoforming, which is a combination of die casting and forging process. It involves injecting a semi-solid slurry of metal into the die, where it is then compacted and solidified under high pressure.

Low pressure die casting

In this method, the molten metal is injected into the die at a low pressure, typically between 1 and 20 atmospheres. This results in a lower porosity and fewer defects in the final casting.

Each of these methods has its own advantages and disadvantages, and the best method for a particular application will depend on factors such as the type of metal being cast, the size and complexity of the part, and the desired properties of the finished product.

Metal Die Casting Processes

Metal casting is a dominant process in the manufacturing industry for producing metal parts in many different shapes, sizes and materials. There are several different casting processes including the primary methods of sand casting, investment casting and die casting.

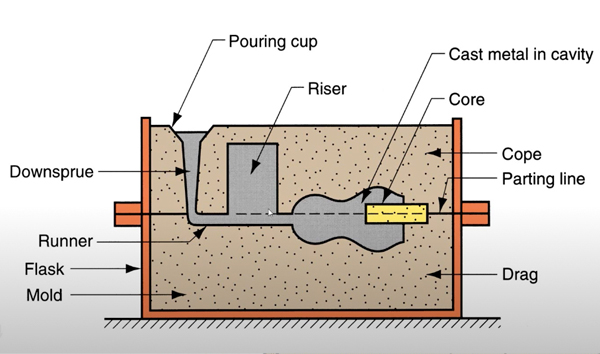

Sand Iron Castings

Sand casting is a process that uses a cope and drag to form a sand pattern that resembles the shape of the part that is being cast. This process is known as an expendable mold process since the sand mold is broken apart and destroyed once the metal part is cast inside of it and subsequently removed from it. The sand casting process uses molten metal which is poured into the sand pattern to fill the void in the sand created by the core. The casting is cooled so the part solidifies, the pattern is opened up, the part is removed and the sand pattern is broken down and usually recycled.

Sand casting is a process that uses a cope and drag to form a sand pattern that resembles the shape of the part that is being cast. This process is known as an expendable mold process since the sand mold is broken apart and destroyed once the metal part is cast inside of it and subsequently removed from it. The sand casting process uses molten metal which is poured into the sand pattern to fill the void in the sand created by the core. The casting is cooled so the part solidifies, the pattern is opened up, the part is removed and the sand pattern is broken down and usually recycled.

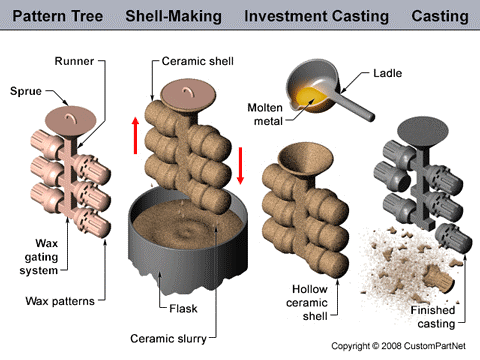

Investment Casting

Investment casting is also known as a lost wax casting process because the pattern is actually made out of a ceramic material formed around wax material that replicates the part or parts being cast. The wax material is melted away from the pattern prior to pouring the molten metal into the mold. Because the mold is formed around the entire wax pattern, investment cast parts can be extremely intricate designs including very thin cross sections.

Investment casting is also known as a lost wax casting process because the pattern is actually made out of a ceramic material formed around wax material that replicates the part or parts being cast. The wax material is melted away from the pattern prior to pouring the molten metal into the mold. Because the mold is formed around the entire wax pattern, investment cast parts can be extremely intricate designs including very thin cross sections.

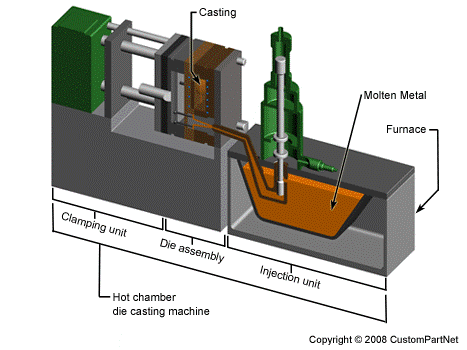

Die Casting

Die casting is another type of process that is called a “permanent mold” process because the mold is reused while molding from part to part. As the name suggests, this process uses a hard die into which liquid metal is injected under pressure to form the part being made.

Die casting is another type of process that is called a “permanent mold” process because the mold is reused while molding from part to part. As the name suggests, this process uses a hard die into which liquid metal is injected under pressure to form the part being made.

Once the metal is injected into the die, it is cooled to harden, the die is opened up and the part is ejected from the die. While the die costs more to manufacture initially, it is very cost effective over time compared to sand or investment casting because it is reusable and very fast.