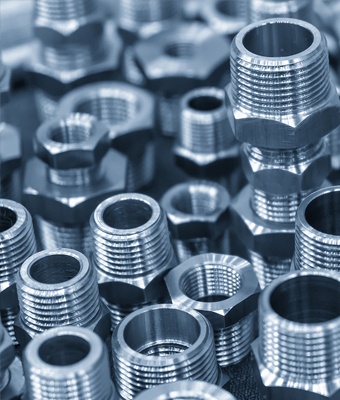

Hydraulic Fittings

Hydraulic fittings are responsible for connecting pipes and hoses, making a whole hydraulic system. Most of the hydraulic fittings are made on the CNC Machines to ensure high-finishing and performance. Once the connection is established, it helps in moving fluids smoothly and maintains pressure throughout the process.

These fittings are available in different materials and sizes at TeraPool Groups.

Companies are shifting to environmentally friendly materials, whether it’s home fittings or industries such as; Automotive, Packaging, Heavy Machinery or Agriculture Equipment. From stainless steel hydraulic fittings to brass, all of them are based on the strict standards to fulfill all your needs for maximizing innovation.

Products Categories

- Assemblies

- Bearings

- Power Transmission Bushings

- CNC Machining

- Power Transmission Chains

- Die Castings

- Clutch Assembly

- Extrusions

- Fasteners

- Forging

- Gearboxes

- Hydraulic Cylinders

- Hydraulic Fittings

- Linear Roller Bearings

- High Pressure Nozzles

- Plastic Molded Parts

- Pulleys

- Rod End Bearings

- Screw Machine Parts

- Hydraulic Seals

- Slewing Bearing Rings

- Sprockets

- Precision Metal Stamping

Hydraulic Fittings

Hydraulic fittings are responsible for connecting pipes and hoses, making a whole hydraulic system. Most of the hydraulic fittings are made on the CNC Machines to ensure high-finishing and performance. Once the connection is established, it helps in moving fluids smoothly and maintains pressure throughout the process.

These fittings are available in different materials and sizes at TeraPool Groups.

Companies are shifting to environmentally friendly materials, whether it’s home fittings or industries such as; Automotive, Packaging, Heavy Machinery or Agriculture Equipment. From stainless steel hydraulic fittings to brass, all of them are based on the strict standards to fulfill all your needs for maximizing innovation.

Hydraulic fittings are available in several dimensions based on your requirements and safety standards. While moving into the market, several hydraulic fitting manufacturers can offer durable quality, but features and resistance can make a big difference.

With time, these fittings are coming up with improved quality and maximum flexibility. The ruggedness of hydraulic fittings is the fundamental reason for choosing it over other products. They offer high stability and speed to a user which makes them satisfied and assure their safety. Hydraulic fittings are also cost-effective due to their long-lasting nature and durability for years.

Hydraulic Fittings

The hydraulic system came into the market in the 20th century but made its place in the industrial sector in the late ’70s that gives a new face to the commercial era. By doing keen research on fluid temperature flow and performance of pipes, the industrial sector adopted it. Later engineers discovered hydraulic fittings are lighter, compact, and efficient performer without damaging any pipes due to external factors. For future developments, hydraulic fittings are of great use, and other than cutting the cost, they can also enhance the durability of products.

How to Choose the Best Hydraulic Fittings?

When hunting for the best hydraulic fittings, you may get confused between wide ranges of options, but it’s essential to consider a few factors before investing in any fittings. Correct size, shape, and style play an important role in preventing leakage and performing appropriately. Let’s get into the buying details and how you can choose the best one of all.

Material

Durability is always a big question mark on the face of any product that we are about to buy. The first thing that you should consider while buying hydraulic fittings is to check the material. Hydraulic fittings are available in various materials including, brass, cast iron, steel, plastic, and aluminum. The most common material people usually buy is metal to tackle the high pressure and for long-term performance. Metal can seal the equipment properly without leakage issues.

Sizes

For high-end functionality, it’s essential to choose the right size of hydraulic fittings. It would be great if you ensure the fitting size, or else the staff of Mechanical Power will guide you throughout the process. A small difference in the measurement may affect the seal and performance of the whole equipment. You can determine the size of a fitting by checking out the vessels it is connected to. Save yourself from the replacement problem and always choose the right size of fittings.

Pressure Ratings

While hunting for the best quality hydraulic fittings, ensure that the product can handle the flow. A properly sealed fitting will prevent leakage by tackling pressure, but it depends on the material. Always check the pressure ratings according to your requirement; never use a low-pressure hydraulic fitting in equipment that works on high-pressure formula. O-ring and Din hydraulic fittings are suitable for high pressure.

Applications

Before the final buying decision, remember to check the compatibility and application range of the fittings. Always check whether the hydraulic fitting is capable of handling a specific application or not? If planning to buy hydraulic fitting for an automotive application, then brass is suitable for such a purpose. Always take guidance from the staff to choose the right hydraulic fittings for your application. The sealing capability and pressure handling are all you need to determine before investing.