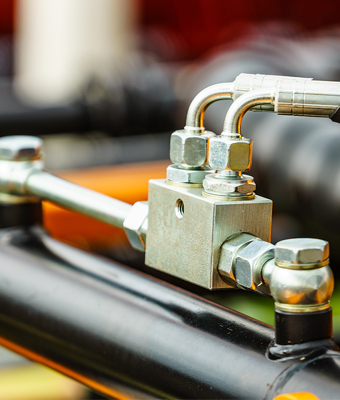

Suppling Hydraulic Cylinders for All Markets

For over four decades, Tera Pool Groups has been supplying custom hydraulic cylinders for the toughest applications.

Our hydraulic cylinders are manufactured and designed to satisfy all operating environments and performance criteria.

- Single-Acting Cylinder

- Double-Acting Cylinder

- Telescoping Cylinder

- Tie-Rod Cylinder

- Welded Cylinder

A hydraulic cylinder is a mechanical actuator used to provide unidirectional force through a unidirectional stroke. Hydraulic cylinders are used in almost every industry and are available in a variety of configurations. The two major types of hydraulic cylinders are; Tie-rod and Welded.

Tie-rod cylinders

Because of the way they are designed, each of these two types can have unique applications. Tie-rod cylinders are usually installed in light to medium duty applications and are generally designed to be repaired or re-packed if necessary.

Welded cylinders

Welded cylinders on the other hand are designed for most applications. They are more complex in design and are generally more difficult to repair because of their design. Hydraulic cylinders generate power from pressurized hydraulic fluid- oil.

The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth.

The barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called the gland) where the piston rod comes out of the cylinder. The piston has sliding rings and seals.

The piston divides the inside of the cylinder into two chambers, the bottom chamber (cap end) and the piston rod side chamber.

The hydraulic cylinder consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth.

The barrel is closed on one end by the cylinder bottom (also called the cap) and the other end by the cylinder head (also called the gland) where the piston rod comes out of the cylinder. The piston has sliding rings and seals.

The piston divides the inside of the cylinder into two chambers, the bottom chamber (cap end) and the piston rod side chamber.

Hydraulic cylinders are used to lift heavy loads or equipment. They can be used in earth-moving equipment to lift or lower the boom, arm, or bucket. These cylinders are also used in hydraulic bending machine, metal sheet sheering machine, particle board or plywood making hot press.

Welded cylinders

Cylinder barrel

The main function of the cylinder body is to contain cylinder pressure. The cylinder barrel is mostly made from honed tubes. Honed tubing is used for hydraulic cylinders that do not need further ID processing. The surface finish of the cylinder barrel is typically 4 to 16 micro inch.

Honing process and Skiving & Roller burnishing process are the two major processes for manufacturing cylinder tube. The piston reciprocates in the cylinder. The cylinder barrel has features of smooth inside surface, high precision tolerance, durable in use etc.

Cylinder base or cap

The cap encloses the pressure chamber at one end. It is connected to the body by means of welding, threading, bolts, or tie rod.

Cylinder head

The head is to encloses the pressure chamber from the other end. It contains an integrated rod sealing arrangement or the option to accept a seal gland.

Piston

The piston separates the pressure zones inside the barrel. It is machined with grooves to fit elastomeric or metal seals and bearing elements.

Piston rod

The piston rod is a typically a hard chrome-plated piece of cold-rolled steel which attaches to the piston and extends from the cylinder through the rod-end head. The piston rod connects the hydraulic actuator to the machine component doing the work. This connection can be in the form of a machine thread or a mounting attachment. The piston rod is highly ground and polished so as to provide a reliable seal and prevent leakage.

Seal gland

The seal gland area of the cylinder head that is fitted with seals to prevent the pressurized oil from leaking past the interface between the rod and the head. The advantage of a seal gland is that it allows for easy removal and seal replacement.

The Hydraulic Cylinder seal gland contains a primary seal, a secondary seal or buffer seal, bearing elements, wiper or scraper and static seal. In some cases, especially in small hydraulic cylinders, the rod gland and the bearing elements are made from a single integral machined part.

Sourcing High-Performance Hydraulic Cylinders

Contact your Tera Pool Groups specialist to discuss your specific application to determine what type of high-performance hydraulic cylinders are right for you and what hydraulic cylinders parts you will need.

Find out why we have become one of the most trusted Hydraulic Cylinder suppliers in Illinois and all of the Midwest.

The Hydraulic Cylinder seal gland contains a primary seal, a secondary seal or buffer seal, bearing elements, wiper or scraper and static seal. In some cases, especially in small hydraulic cylinders, the rod gland and the bearing elements are made from a single integral machined part.